乐高英雄工厂游戏,乐高英雄工厂游戏下载手机版

网上有很多关于乐高英雄工厂游戏,乐高英雄工厂游戏下载手机版的知识,也有很多人为大家解答关于乐高英雄工厂手游的问题,今天白鹿网游网为大家整理了关于这方面的知识,让我们一起来看下吧!

本文目录一览:

1、乐高英雄工厂手游

乐高英雄工厂手游

The Group control strategy for the LEGO group

乐高玩具制造(嘉兴)工厂冷冻机房群控系统

The up and down control strategy of the chillers

冷机加减控制方案

材料来源:195152396@qq.com

Table of Contents目录

Charter 1 Proposal summary 第1章 概述

Charter 2 Design Standards 第2章 设计依据

Charter 3 Demand analysis 第3章 需求分析

3.1 Electromechanical equipment being controlled and managed automatically will be realized.实现各种机电设备的自动控制和管理

3.2 The detection of alarm protect 检测报警保护

3.3 The standard bus commission interface will be provided for accessing the existing system提供标准总线通信接口接入现有系统

Charter 4 system design 第4章 系统设计

1.1 The start of the chiller 冷机启动

1.2 Up stage control 加机控制

1.3 Down stage control 减机控制

1.4 Capacity regulator能量调节

1.5 The VSD control of first-chilled pump 一次冷冻水泵变频控制

1.6 The interface and the control objects with the group control system 与群控系统的界面和控制对象

1.7 The control flow chart

1.8 System architecture 网络架构

Charter 5 Optimizing strategy 第5章优化策略

5.1 System open question系统开放性问题

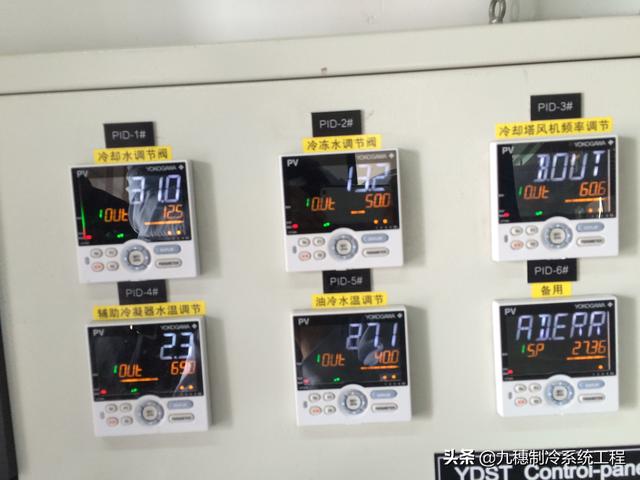

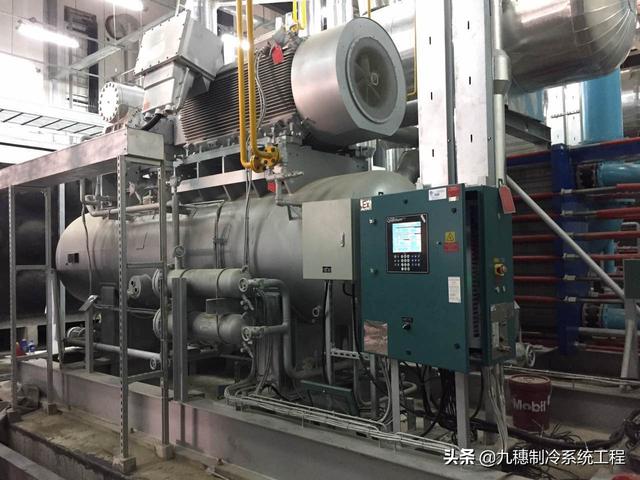

åthe mainly propose for this project chiller group control. 项目基本情况:本次项目主要是冷机群控系统中冷机加减机控制部分和相应一次冷冻水泵的启停控制。

The main device is as follows主要包括以下设备:

Six chillers (one 3900KW chiller, three 5800KW chillers, another two are added for future), six first chilled pumps (one 45KW VSD pump, three 75KW VSD pumps, another two are added for future), some energy meters.冷机6台(本次1台3900KW冷机,3台5800KW冷机,另外两台为日后增加),一次冷冻水泵6台(1台45KW变频泵,3台75KW变频泵,2台75KW变频泵日后增加),能量计等设备组成。

The group control of chillers is controlled by other automatic control company. The JCI only control the quantity of the chillers, the related cooling valves and the first chilled pumps. In order to control the chiller quantity stably and energy-efficiently according to the building Load, the FEC series controller and Network automation controller are choose in this system. 本群控系统由其他自控厂家来完成,我们仅对冷机加减机控制和相关冷却水阀门和一次冷冻水泵的启停进行控制。采用江森的FEC系列DDC和NAE网络引擎控制技术根据空调负荷对冷冻机组进行台数控制,在确保冷冻机稳定运行的基础上,达到高效和节能的目的。

Charter 2 Design Standards 第2章 设计依据In order to insure the system following the network technology and the high reliability, the system design comply with the following design reference, codes and standards.为了保证系统既能适应当今网络技术的发展,又具有极高的可靠性,系统设计以及设备制造遵从以下设计依据、规范和标准:

² Technologic specifications 技术规格说明书

² Project drawings 项目图纸

² Intelligent building design standards智能建筑设计标准 (GB/T50314-2006);

² Code for acceptance of quality of Intelligent build ing systems智能建筑工程质量验收规范 (GB 50339-2003)

² Code for design of heating, ventilation and air conditioning采暖通风与空气调节设计规范(GB50019-2003)

² Code for engineering design of generic cabling system for building and campus 建筑与建筑群综合布线系统工程验收规范 (GB 50312-2007)

² Code for acceptance of construction quality of building electrical engineering建筑电气工程施工质量验收规范 (GB 50303-2002)

² Unified standard for constructional quality acceptance of building engineering建筑工程施工质量验收统一标准 (GB 50300-2001)

² Design standard for energy efficiency of public buildings公共建筑节能设计标准 (GB 50189-2005)

² Evaluation standard for green building 绿色建筑评价标准 (GB 50378-2006)

² Code for acceptance of construction of intelligent building智能建筑施工及验收规范 (DG/TJ08-601)

² Code for construction and acceptance of Industrial Automation Instrument Engineering工业自动化仪表工程施工及验收规范 (GB50093-2002)

² Standard for inspection of building automation system建筑设备监控系统检验标准 (DB/TJ08-605-2004)

² Code for Distributed Control System engineering design分散型控制系统工程设计规定(HG/T20573-2012)

² Code for electrleal design of civil buildings民用建筑电气设计规范 (JGJ16-2008)

² Code for design of automatic fire alarm system 火灾自动报警系统设计规范(GB50116-1998);

² The international standard of information technology interconnection信息技术互连国际标准(ISO/IECl1801-95);

² Code for fire protection design of tall buildings高层民用建筑设计防火规范(GB50045-95);

² Low-voltage switchgear and control gear assemblies低压成套开关设备和控制设备 (GB7251.1-2005);

² Low-voltage switchgear and control gear低压开关设备和控制设备 (GB 14048-2008)

² Other rules and norms related industries其他相关行业的规定及规范

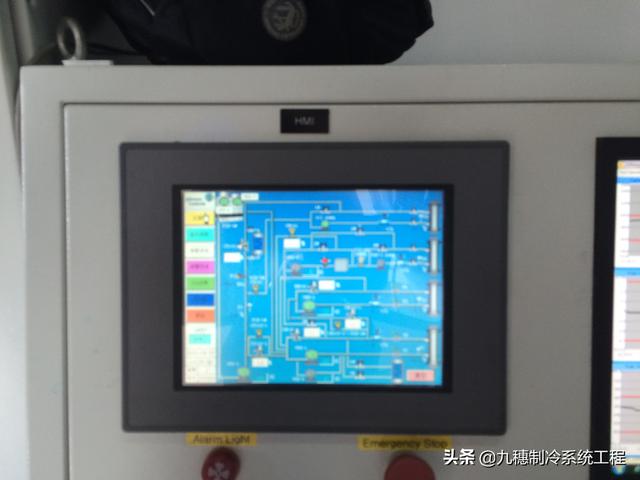

Charter 3 Demand analysis 第3章 需求分析The perfect combination between the up down control and the chiller group control is the project owners ‘prospect. And the up down control, related first-chilled pump and the related electronic valves are controlled automatically. All the control data will be exchanged with the group control system, the system running status and fault will be outputted.业主希望冷机加减机控制和整体冷机群控完美结合,实现冷机加减机、相应一次冷冻水泵、相关电动阀门实现全自动控制,所有数据要与群控系统互换,并可进行系统运行状况的判断输出报警。

3.1 Electromechanical equipment being controlled and managed automatically will be realized.实现各种机电设备的自动控制和管理

Such as: load automatic control, the programed start and stop of first-chilled pump, the number of running chillers automatic control, the automatic receive of device overload alarm, the backup device automatic switchover. 如负荷的自动控制、一次冷冻水泵设备的程序启停、机组开启台数的自动控制,设备过载警报的自动接收,备用设备自动切换运行等。

3.2 The detection of alarm protect 检测报警保护

The commission between the BA system and the chiller will be realized for running data collection and provide a series interlock protection measures to insure the system stably running. The popup alarm information will remind the operator when the device is fault. 系统与冷机通讯,采集运行数据,提供一系列连锁保护措施保证系统稳定运行,当设备发生故障时,能立即弹出报警信息提醒操作员。

3.3 The standard bus commission interface will be provided for accessing the existing system提供标准总线通信接口接入现有系统

The group control system will provide the standard bacnet protocol bus commission interface for the building automatic system. 群控系统可提供标准通讯接口BACNET供楼宇自控系统整合接驳。

Charter 4 system design 第4章 系统设计1.1 The start of the chiller 冷机启动

1. The chiller start command is send by the group control system, the DDC will choose one from the chiller 02~04 which running time is minimum when the DDC receives the start command. . 冷机启动命令由群控系统发出,DDC接收到启动命令后中运行时间最小的一台冷机进行开机。

2. Before start the chiller, the cooling valve and the first-chilled pump should be started first. The chiller will be started after receiving the normal signal of the valve and pump.冷机启动之前首先开启冷却水阀门和一次冷冻水泵,等待接收到阀门开启冷却水正常信号和冷冻水泵运行正常信号3分钟后启动冷冻机。

3. Another chiller will be started again when the cooling, chilled or the first chiller is fault. 当冷却水故障或者冷冻水泵故障、冷机有故障时系统自动从新选择一台冷机运行。

4. The small chiller will be choose firstly in the transition season or reserved after the down stage.过渡季首先运行CH01小型冷机,或者减机后最后保留小型冷机

1.2 Up stage control 加机控制

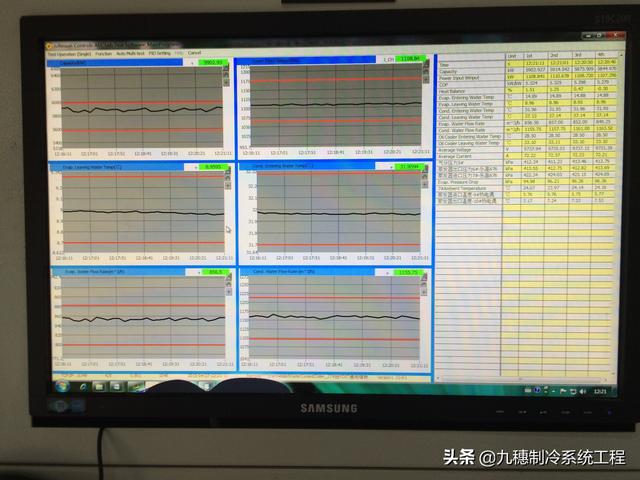

The chiller will monitor the terminal load every 20 minutes. The system still to wait for 10 minutes when the requirement of heating load just over the running chiller’s capacity or the requirement of the chilled water flow just over the running chiller ‘s capacity occurs, and the system still overload, the system will add another chiller automatically.冷机每20分钟会监测末端的负载情况,当热负荷的需求恰好超过在线运行的冷水机组的能力时,或者冷冻水流量的需求恰好超过在线运行的冷水机组的能力时两种任何一种状况满足时系统仍等待10分钟仍然处于超负荷状态系统自动加机。

1.3 Down stage control 减机控制

The chiller will monitor the terminal load every 20 minutes. If the number of running chillers are N; firstly, set load switching point, then judge that whether the rated load of (n-1) chiller is equal to the building load of the current N chillers or not, if yes and judge that stopping one running chiller will not lead to requirement of the chilled water for the building over the other running chiller’s capacity. The system still to wait for 10 minutes at low building load status, then the system will subtract one chiller. 冷机每20分钟会监测末端的负载情况,如果有N台冷水机组在线运行,判定一个负荷量的切换点,此时N-1台冷水机组的额定负荷能力恰好等于当前N台冷机的负荷量,并且,停止一台在线运行冷机将不会导致大楼对冷冻水的需求量大于其余正在运行的冷水机组的能力时再等待10分钟仍然处于低负荷状态系统自动减机。

1.4 Capacity regulator能量调节

1. Adjust the slide valve position in order to make the chiller in maximum efficiency status 为了使冷机的运行效率最大化,调节滑阀位置使冷机的效率最大化。

The slide valve position will be opened from 60% when the chiller starts, and the DDC will regulator the slide valve position from 60% to 98%当冷机开机时滑阀位置从60%慢慢开启,DDC调节滑阀位置从60%~98%(可设置位置区间)之间。

2. Keep one chiller as load regulator, other chillers’ slide valve are opened maximum in order to maximum the chillers’ efficiency when great than two chillers are running 当两台以上冷机在运行时为了冷机效率最大化,除一台冷机作为负荷调整使用以外,剩余运行的冷机滑阀位置开到最大,使功率最大化,剩余一台冷机调节滑阀位置,满足当前负荷。

1.5 The VSD control of first-chilled pump 一次冷冻水泵变频控制

The vsd pumps are controlled according to the terminal building load, the full-loaded chillers will go to power frequency running, at this situation, the flow of the chiller which is adjusting its slide valves is regulating according the terminal building load. The chilled water is open chilled water tank system, and every VSD pump can working at different frequency. 根据末端负载流量情况控制变频泵,运行满载的冷机趋于工频运行,调节滑阀位置的冷机流量根据末端流量进行变频调节。本次系统中冷冻水不是分水器而是开式冷冻水箱系统,每台变频泵可按不同的频率工作。

1.6 The interface and the control objects with the group control system 与群控系统的界面和控制对象

1. The JCI controllers have the standard bacnet protocol for commission with the third part devices. 江森DDC采用楼宇控制标准协议BACnet TCP/IP协议与外界通讯,

2. The running status, energy signal of every loop and flow information will be collected for the JCI controllers from the group control system.江森DDC需要采集信号有群控系统运行信号、每回路上的能量计能量信号和流量信号

3. Running parameters of every chiller, the status, fault and frequency signal of first-chilled pumps can be output for integration.江森DDC输出信号有每台冷机的运行参数、一次冷冻泵的运行状态、故障、频率反馈等信号

4. Control object: the cooling valve, start/stop and frequency control of first-chilled pump, start/stop and parameters of chillers.控制对象:冷却水阀门控制

一次冷冻水泵启停和频率控制

冷机监视和启停

1.7 The control flow chart

1.8 System architecture 网络架构

The management layer network entirely based on the Ethernet (TCP/IP) from the above structure diagram, using the latest technology, and adopt international open standard protocol of BACnet communication.从以上的网络结构图可以看到,管理层网络完全建立在以太网(TCP/IP)基础上,利用了网络最新技术,并全部采用国际开放标准协议BACnet进行通讯。

The site controlled devices such as pumps, valves are coordination control by the DDC controller. The site DDC controller and the chiller interface are accessed the Ethernet via the NAE. 现场被控设备,如水泵、阀门等由DDC控制器进行统一的协调控制。现场DDC控制器通过网络控制引擎(NAE)接入以太网;冷水机组配置接口网关后也通过网络控制引擎NAE接入以太网。

The third part group control system (which comply the international standard Bacnet protocol) can read /write data to the local group control system. Such as: above BA system, if authorized, it can collect data and control the chiller, pump and all other devices which are in the chilled water station system.在该以太网上,第三方群控系统(只要遵守国际标准免费协议BACnet)都可以任意读写群控系统的数据,例如:上图的BA系统,经过授权,它可以对冷冻站群控系统中的机组、水泵、一次变频水泵等所有设备进行数据采集和控制。

Charter 5 Optimizing strategy 第5章优化策略1、Rotation function of devices设备轮换功能

After the current devices have run a lone time, the user may need to artificially switching another set of system operation, the conventional group control system should take the corresponding equipment shut down then re issued command to start the rotation function, but the system has "bumpless switching" function, allows the operator to start the equipment rotation function through the PC command the system will automatically choose to participate, the rotation of the chiller , open the water valve and pump correspondingly and then open the participation in the rotation of the chiller. after a period of time delay, finally closing a set of original running system在当前一组设备长时间运行后,用户可能需要人为的切换另外一套系统来运行,常规的群控系统需要先把相应设备关闭后重新发出开启命令才能启动轮换功能,但本系统具有“无扰切换”功能,允许操作员通过上位机命令启动设备轮换功能,系统将自动选择参与轮换的冷机,打开相应的水阀及水泵,然后开启参与轮换的冷机;延时一段时间后,最后关闭原先运行的一组系统。

2、Adding chiller forced function强制加机功能

In some situations, chiller cannot reach the design rated power, such as: chiller pipe scaling effects the efficiency, the chiller working conditions over the design working conditions and so on, under these conditions, chiller will not reach its normal working load, this procedure does not meet with machine conditions, leading to the construction of the load cannot be met in a timely manner. Now, this system has imposed machine function can effectively avoid this problem: when the chilled water supply temperature exceeds the set point of 3 degrees above, and continued for more than 20 minutes (adjustable), the program will add machine operation, in time to meet the load requirements.在某些工作条件下,冷机可能无法达到其设计时的额定功率,例如:冷机管道结垢影响效率、冷机的工作条件超过了设计工作条件等等,在这些条件下,冷机将无法达到其正常工作负荷,此时程序没有满足加机的条件,导致建筑的负荷无法及时得到满足。此时,本系统具有的强制加机功能可以有效的避免这个问题:当冷冻水供水温度超过其设定点3度以上,并且持续20分钟以上(可调整),程序将进行加机操作,及时满足负荷的要求。

3、Avoiding add machine operation when the system is approaching shut down临近系统关闭时避免加机操作

The last several hours in a day, under normal circumstances the building load will decline. But there may be a short time fluctuation occasionally, caused by adding machine unnecessary operation of the system. The program reserve to avoid adding machine function, according to user needs to set in a specified period of time to avoid adding machine operation.在系统一天中运行的最后几个小时内,一般情况下,建筑冷负荷会下降。但偶尔可能会有短时间的波动,引起系统不必要的加减机操作,本程序预留避免加机功能,可根据用户需要设置在规定时间段内避免进行加机操作。

4、Assist the daily maintenance function辅助日常维护功能

When the device is in a repair state, or for various reasons , do not want a unit or the pump to participate in group control, in the device setting, set the chiller not available, the unit or the pump will not participate in group control logic当设备处于维修状态,或者由于各种原因不想让某台机组或水泵参与群控的话,只需在系统中将该设备设置为不可用状态,则此机组或水泵将不参与群控逻辑。

5.1 System open question系统开放性问题

The group control system can commission with the existing building automation system, and can provide standard protocol for BAS system. Through the provision and distribution of authority, can monitor and control of the group control system in the existing system remotely, and can be read but not limited to, the following parameters:群控系统能与现有的楼宇设备自控系统进行通信、提供开放的通讯接口供BAS系统接收,通过权限的设置及分配,可在原有系统上可以远程监测并控制本群控系统,可以读取但不仅限于下列参数:

l Chiller running status 制冷机运行状态:

Supply /return temperature of chilled water, Supply /return temperature of cooling water, refrigerating fluid pressure, oil pressure of evaporator /condenser, motor current percent, saturation temperature, oil temperature of evaporator /condenser, running hours of compressor, running time of compressor, exhaust temperature of compressor.冷冻水供/回水温度、冷却水供/回水温度、蒸发器/冷凝器内制冷剂压力、油压差、电动机电流值的百分率、蒸发器/冷凝器的饱和温度、油温及油压、压缩机运行小时数、压缩机启动次数、压缩机排气温度

l Chiller alarm 制冷机故障报警:

The refrigerant pressure, low temperature of chilled water, refrigerant high pressure, high temperature and high pressure lubricating oil, lubricating oil, lubricating oil pressure, chilled water flow is too small, the cooling water flow is too small, the compressor motor current exceeds the limit, the starter failure etc.冷媒低压、冷冻水温过低、冷媒高压、润滑油高温、润滑油高压、润滑油低压、冷冻水流量过少、冷却水流量过少、压缩机电动机之电流超过限量、启动器失灵等等

l The detail parameters of the chiller interface 制冷机接口详细参数如下表:

BACnet

Object

BACnet

Object Name

Point List Description

AV5

LEAVING CHW TEMP

冷冻水供水温度

AV6

ENTERING CHW TEMP

冷冻水回水温度

AV7

EVAPORATOR PRESSURE

蒸发器压力

AV8

CONDENSER PRESSURE

冷凝器压力

AV9

OIL DIFERENTIAL PRESSURE

油压差

AV10

ENTERING COND WATER TEMP

冷却水回水温度

AV11

LEAVING COND WATER TEMP

冷却水出水温度

AV12

MOTOR CURRENT PCT FLA

电机电流百分比

AV13

PHASE A MOTOR CURRENT

VSD A相电流

AV14

PHASE B MOTOR CURRENT

VSD B相电流

AV15

PHASE C MOTOR CURRENT

VSD C相电流

AV19

LEAVING CHW TEMP ACT SP

实际冷冻水供水温度设定值

AV20

MOTOR CURRENT ACTUAL SP

实际电流上限设定值

AV21

EVAP SATURATION TEMP

蒸发器饱和温度

AV22

COND SATURATION TEMP

冷凝器饱和温度

AV23

DISCHARGE TEMP

排气温度

AV24

OIL SUMP TEMPERATURE

油槽温度

AV26

ACCUM OPERATING HOURS

机组运行时间

AV27

ACCUM SYSTEM STARTS

机组启动次数

AV28

OIL SUMP PRESSURE

油槽压力

AV29

OIL PUMP PRESSURE

油泵压力

BV5

COMPR MOTOR STATUS

电机状态

BV9

CHW FLOW SWITCH STAT

冷冻水流开关状态

MV1 /AV401

UNIT OPERATION CODE

机组运行代码

MV2 /AV402

UNIT SAFETY FAULT CODE

机组安全故障代码

MV3 /AV403

UNIT CYCLING FAULT CODE

机组循环故障代码

MV4 /AV404

UNIT WARNING FAULT CODE

机组警告故障代码

MV5 /AV405

UNIT CONTROL SOURCE

机组控制源

AV40

VSD OUTPUT FREQUENCY

VSD输出频率

AV110

VSD INTERNAL AMBIEN TEMP

VSD内部环境温度

P56

运行代码

0

机组停止 - 准备启动

Unit Stopped - Ready To Start

1

机组停止 - 本地关机

Unit Stopped - Local Shutdown

2

机组停止 - 远程关机

Unit Stopped - Remote Shutdown

3

机组停止 - 警告

Unit Stopped - Warning Active

4

机组停止 - 循环关机

Unit Stopped - Cycling Shutdown

5

机组停止 - 安全关机

Unit Stopped - Safety Shutdown

6

机组启动禁止

Unit Start Inhibit

7

机组启动中

Unit Starting

8

机组运行 - 正常

Unit Running - No Abnormal Condition

9

机组运行 - 警告

Unit Running - Warning Active

10

机组运行 - 关机前卸载

Unit Running - Chiller Unload Before Shutdown

11

机组降级Unit Lockout Delay

12

机组运行 - 修正运行Unit Running - Modified Run*

13

机组停止 - 内部关机* Unit Stopped - Internal Shutdown*

P57

安全故障代码

0

无安全故障代码No Abnormal Condition

1

蒸发器 - 低压Evaporator - Low Pressure

2

蒸发器 - 出水温度传感器故障Evaporator - Transducer Or Leaving Liquid Probe

3

蒸发器 - 传感器故障Evaporator - Temperature Transducer

4

蒸发器 - 高压触点开路Condenser - High Pressure Contacts Open

5

蒸发器 - 高压Condenser - High Pressure

6

蒸发器 - 压力传感器超量程Condenser - Pressure Transducer Out Of Range

7

辅助安全 - 触点关闭Auxiliary Safety - Contacts Closed

8

排气 - 低温Discharge - Low Temperature

9

排气 - 高温Discharge - High Temperature

10

油 - 高温Oil - High Temperature

11

油 - 低压差Oil - Low Differential Pressure

12

油 - 高压差Oil- High Pressure

13

油 - 油泵压力传感器超量程Oil- Filter Clogged

14

油 - 油槽压力传感器超量程Control Panel - Power Failure

15

油 - 高压Oil- High Pressure

16

油 - 过滤器堵塞Oil- Filter Clogged

17

油 - 密封压差过低

19

油分离器 - 低液位

20

油 - 未达到变频泵设定点

21

控制面板 - 电源故障Control Panel - Power Failure

24

Thrust Bearing - Proximity Probe ClearaNAE

25

Thrust Bearing - Proximity Probe Uncalibrated

29

VSD - High Heatsink Temperature

30

VSD - 105% 电机电流过载

P58

CYCLING FLT

0

无循环故障No Abnormal Condition

1

多单元循环Multi-Unit Cycling - Contacts Open

2

系统循环System Cycling - Contacts Open

3

油 - 温差过低Oil - Low Temperature

4

油 - 低温Oil - Low Temperature

5

控制面板 - 电源故障Control Panel - Power Failure

6

冷冻水出水温度 -低温Leaving Chilled Liquid - Low Temperature

7

冷冻水出水温度 -水流开关开路Leaving Chilled Liquid - Flow Switch Open

8

冷凝器 - 水流开关开路Condenser - Flow Switch Open

9

电机控制器- 开路Motor Controller - Contacts Open

10

电机控制器- 失电Motor Controller - Loss Of Current

11

电源故障Power Fault

12

控制面板 - 时间表

13

启动器 -低供电线电压

14

启动器 -高供电线电压

15

Proximity Probe - Low Supply Voltage

16

油 - Variable Speed Pump - Drive Contacts Open

17

VSD / MVVSD - 初始化失败

18

VSD / MVVSD 关闭 - 请求故障数据...

19

VSD - A相瞬间高电流

20

VSD - B相瞬间高电流

21

VSD - C相瞬间高电流

22

VSD - Phase A Gate Driver

23

VSD - Phase B Gate Driver

24

VSD - Phase C Gate Driver

25

VSD / MVVSD - 单相输入电压

26

VSD - DC 总线电压过高

27

VSD - Logic Board Power Supply

28

VSD - DC总线电压过低

29

VSD - DC 总线电压不平衡

30

VSD - 内部温度过高

31

VSD - 电流系数选择错误

乐高玩具英雄工厂听说更新到第五代了请问更新了哪些?

英雄工厂第五代 上半年的是超级华光 洛卡 清风 巨霸 火牛魔 沙虫怪 绿晶魔 巨岩怪下半年资料还不完全 英雄是强袭 翼豪 突波 飞行装洛卡 恶霸我知道冰封兽 雷电龙 希望对你有帮助

以上就是关于乐高英雄工厂游戏,乐高英雄工厂游戏下载手机版的知识,后面我们会继续为大家整理关于乐高英雄工厂手游的知识,希望能够帮助到大家!

版权声明

本文内容由seo小编辑收集和互联网用户自发贡献,该文观点仅代表作者本人。本站仅提供信息存储空间服务,不拥有所有权,不承担相关法律责任。如发现本站有涉嫌抄袭侵权/违法违规的内容, 请发送邮件至 wnw678@qq.com 举报,一经查实,本站将立刻删除。